FineFinish continually invests in the latest gear cutting machines and tooling to ensure our gear teeth are precisely cut to very tight tolerances each and every time. Since 1998 FineFinish has been providing both stock and custom engineered mechanical components. We are not limited to manufacturing parts; we also design, manufacture and assemble custom subassemblies with world-class quality and reliability for all applications.

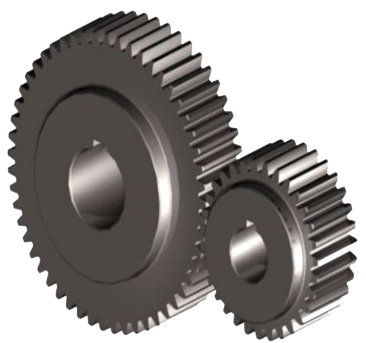

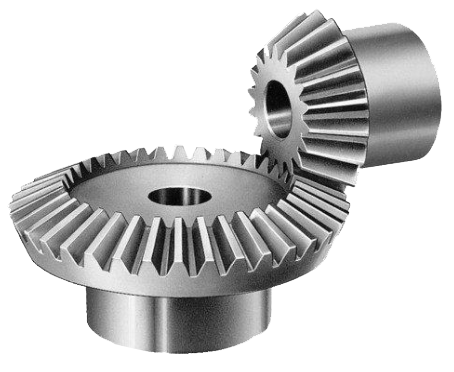

As a precision gear and small mechanical component manufacturer we excel in every process and every gear types.

We use materials such as quenched and tempered steel, case hardening steel, stainless steel, grey cast iron, non-ferrous metals, aluminium, titanium and plastics. We also use case hardening processes available on the market.

We offer A-Z solutions from sourcing material, manufaturing for parts which you supply to delivering and installing the gear wheel.

HIGH QUALITY gear cutting and prototyping for spur gears, helical gears, splines, and worms. All cutting jobs are qualified and validated by our state-of-the-art HAAS machines.

Whatever your gear manufacturing requirements, for a competitive quotation please contact us. Our expert engineer will be happy to advise and help you.